Ingeniería

La digitalización y la creación de prototipos aumentan la productividad

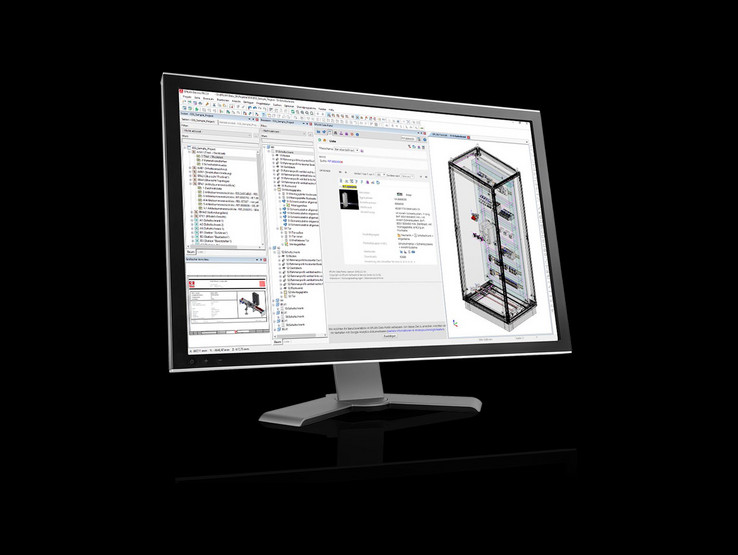

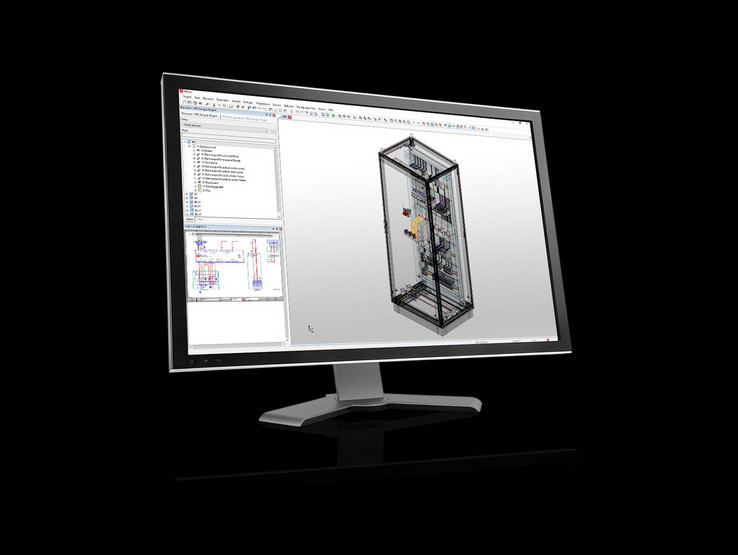

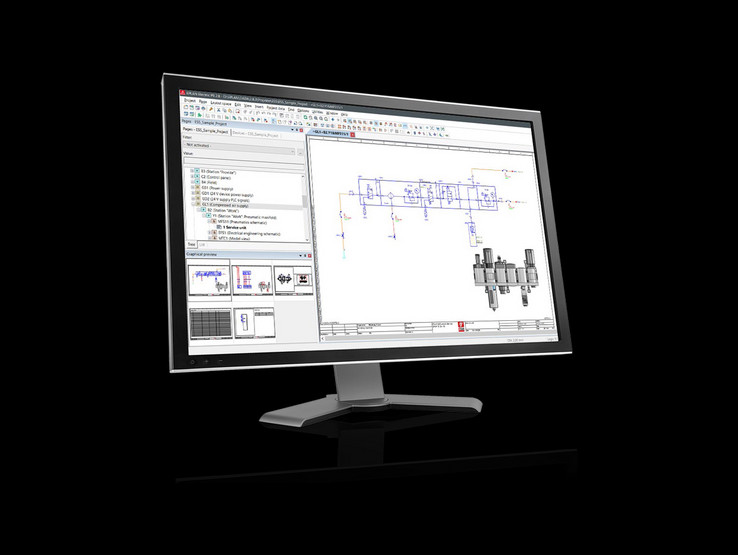

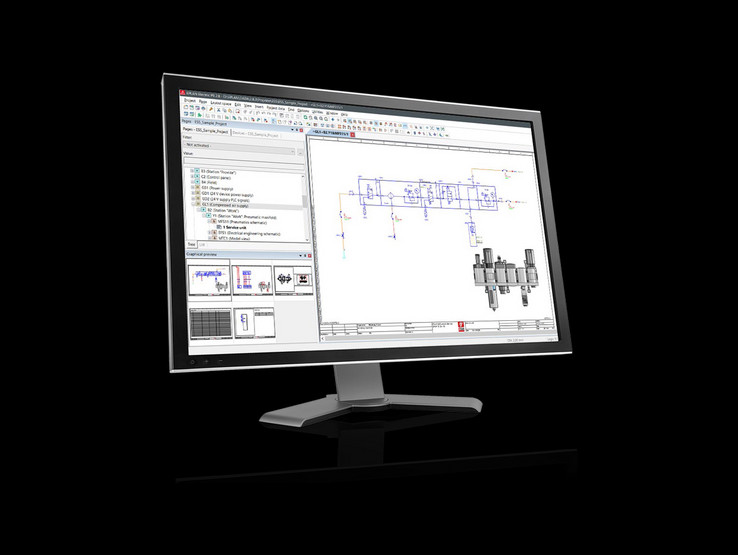

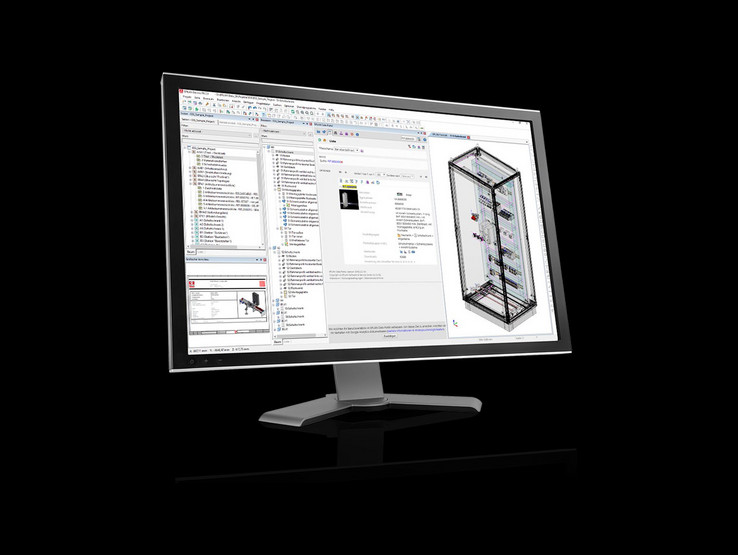

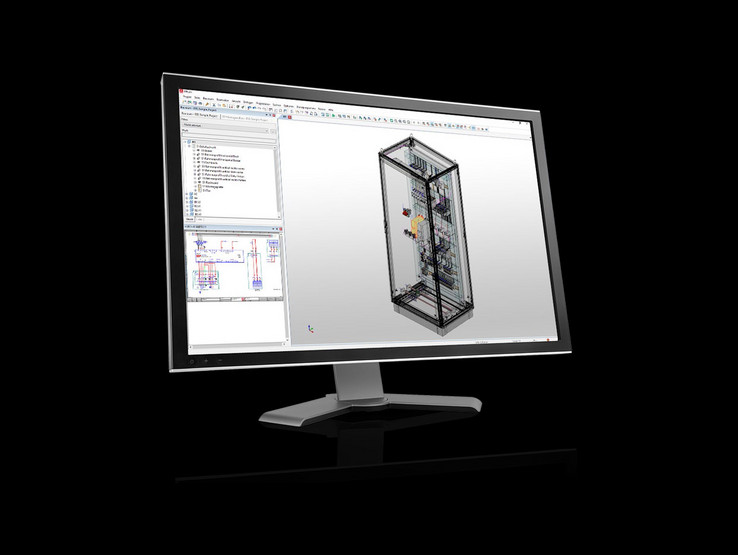

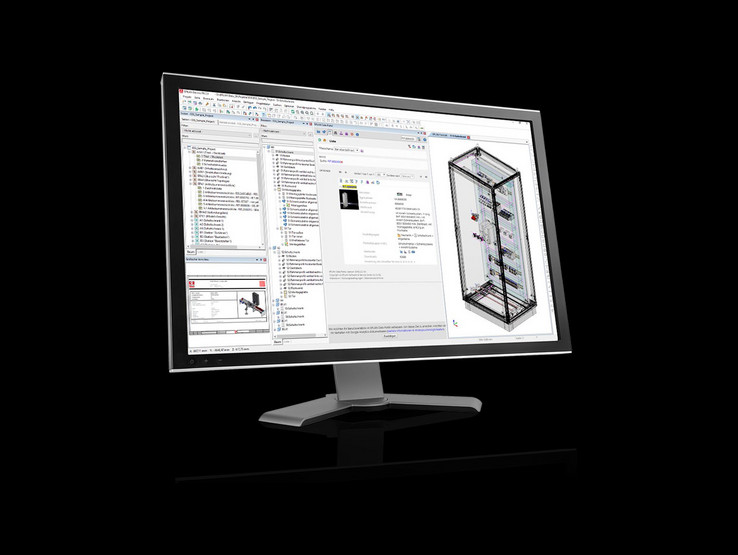

El armario eléctrico se planifica y diseña digitalmente en el departamento de ingeniería. Las soluciones de software de EPLAN funcionan a la perfección para generar una base de datos centralizada de todo el proceso de la cadena de valor: paso a paso, se crea el gemelo digital del producto real como un modelo de datos consistente. Los datos en 3D representan la cubierta y los accesorios del prototipo virtual. Estos datos se complementan con componentes específicos del proyecto e información sobre el cableado. Como parte de este proceso, todos los datos de ingeniería están disponibles en un entorno centralizado al que también se puede acceder en los pasos posteriores del proceso. De este modo, incluso la personalización masiva puede automatizarse y llevarse a cabo de forma rentable.

EPLAN Data Portal

- Encuentre rápida y fácilmente datos estandarizados de componentes y aplicables internacionalmente.

- Benefíciese de un claro ahorro de tiempo durante la planificación del proyecto en comparación con los procesos manuales.

- Aumente considerablemente la calidad de su documentación.

EPLAN Preplanning

- Mantenga todos los datos de su sistema, máquina o edificio bien estructurados y a la mano en todo momento.

- Preplanifique la información fundamental, como los datos de señales, tuberías y cables, sobre una base gráfica.

- Todo el personal involucrado tiene fácil acceso a los datos de ingeniería recopilados desde las primeras fases del proyecto, y conserva este acceso durante todo el proceso y más allá.

- La utilización de EPLAN Preplanning en la fase de cotizaciones y la transferencia transparente de datos a ingeniería reducen considerablemente los plazos de desarrollo.

EPLAN Pro Panel

- Desde la generación de esquemáticos de circuitos y diseños de montaje, hasta la integración de la producción: realice todas las tareas en un único sistema.

- Al proporcionar información sobre los pedidos y documentos de fabricación completos, se obtiene una fabricación automatizada de sus armarios y tableros.

- Reduzca los tiempos y los costos de producción, con una calidad superior.

- Trabaje de forma rentable: desde un proyecto individual de un solo lote, hasta la producción en serie.

Consultoría para la cadena de valor

- Los expertos de Rittal trabajan con los clientes y utilizan la herramienta de análisis de procesos para identificar posibles mejoras de eficiencia en todos los procesos.

- Los servicios de consultoría ofrecen recomendaciones prácticas para ahorrar tiempos y costos.

RiPanel

- Seleccione su tablero y los accesorios, y configúrelos con facilidad.

- Planifique y visualice los cortes y perforaciones en 3D en tiempo real.

- Ahorre tiempos con los documentos y datos de producción, que se generan automáticamente al final del proceso de configuración: un archivo CAD para toda la configuración, un archivo CNC para el mecanizado directo, y datos con configuraciones específicas del cliente para su envío a EPLAN Pro Panel.

- Tras la fase de planificación, envíe la configuración directamente o solicítela en línea.

Power Engineering

- Nuestro sistema modular le permite reducir considerablemente los costos de planificación, solicitud y montaje: sólo tiene que seleccionar los conjuntos y colocarlos en el gráfico.

- Las listas de los componentes, las credenciales técnicas y la documentación se generan automáticamente.

- Rittal ofrece asistencia técnica con previa solicitud.

Product Functions Design

Schematic design with ECAD software – the entire value chain subsequently benefits from consistent engineering data .

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN Fluid

- Save time by speeding up time-consuming steps and minimizing the need to consult specialist departments

- Macro technology enables you to store standards and expertise in the system so they can be reused later on

- Fluid technology can be planned in line with the latest ISO 1219 or IEC 81346 standards with a mechatronic approach

Checking & Correcting

The schematic is checked for conformity to standards, completeness and correctness before it is made available for subsequent processes. This way, errors in subsequent processes, e.g. in the unambiguous designation of components or in the complete description of electrical connections, can be avoided. Ideally, this is done automatically with the support of the ECAD software.

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN Fluid

- Save time by speeding up time-consuming steps and minimizing the need to consult specialist departments

- Macro technology enables you to store standards and expertise in the system so they can be reused later on

- Fluid technology can be planned in line with the latest ISO 1219 or IEC 81346 standards with a mechatronic approach

Mechanical Infrastructure

With a view to the customer’s requirements, the location, the environmental conditions and the space required for the installation of the electrical and fluid components specified in the schematic, the appropriate type of enclosure is selected, dimensioned and supplemented with the necessary accessories.

RiPanel

- Simply select enclosure and accessories and configure your new enclosure with ease

- Cut-outs and drilled holes are planned and visualized in 3D in real time

- Save a lot of time – production documents and data are generated automatically at the end of the configuration process: a CAD file for the entire configuration, a CNC file for straightforward machining, data with customer-specific configurations for forwarding to EPLAN Pro Panel

- After the planning stage, you can submit an enquiry for the configuration or order it online directly

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

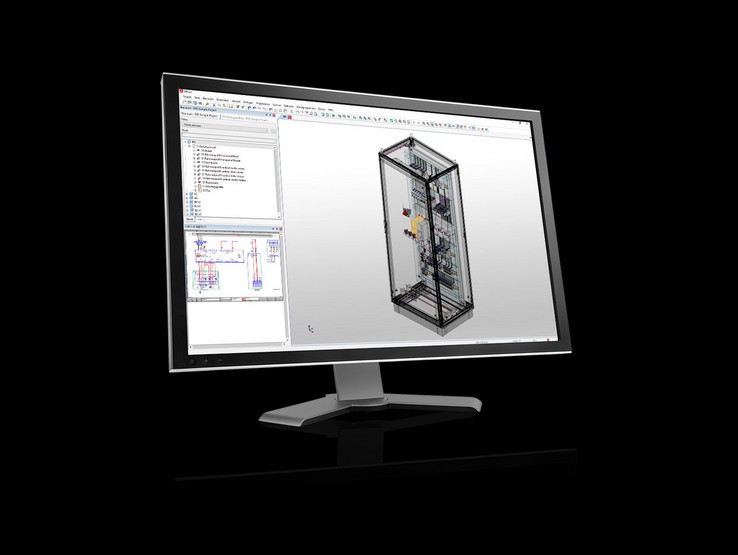

Digital Twin

The digital twin brings great opportunities concerning manual process steps as well as for automation and digitalization of all process steps in panel building, e.g. mechanical processing, wire prefabrication, wiring and terminal assembling.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

Thermal Design & Dimensioning

Customer requirements, ambient conditions at the installation site, electrotechnical components and their power dissipation as well as the defined assembly layout of the digital twin define the framework conditions for configuring and dimensioning the optimal climate control solution and the correct distribution of the air flows.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

Thermal Design Integration

- Avoid planning mistakes thanks to the visualization of hot spots and exclusion zones dictated by ventilation requirements

- Minimize downtimes and reduce the number of service assignments

- Lower costs and improve process quality

RiTherm

- RiTherm takes care of all aspects of complex calculations for climate control requirements

- Benefit from huge time savings and improved reliability

- The calculation produces an optimum climate control solution

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW